ABOUT ONTARIO DYNAMICS

Designing and Delivering Complete Automation, Machinery and Product Solution

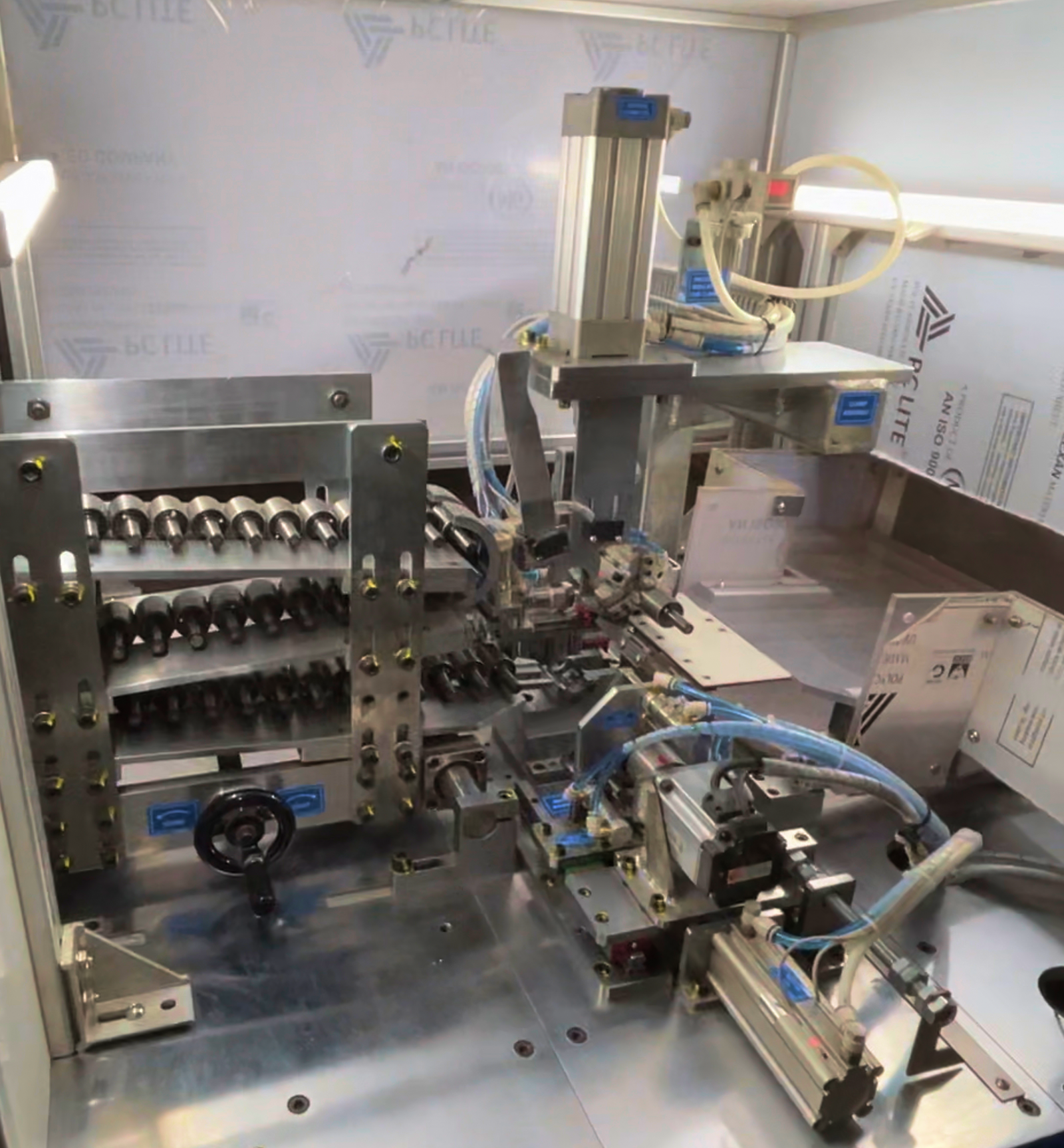

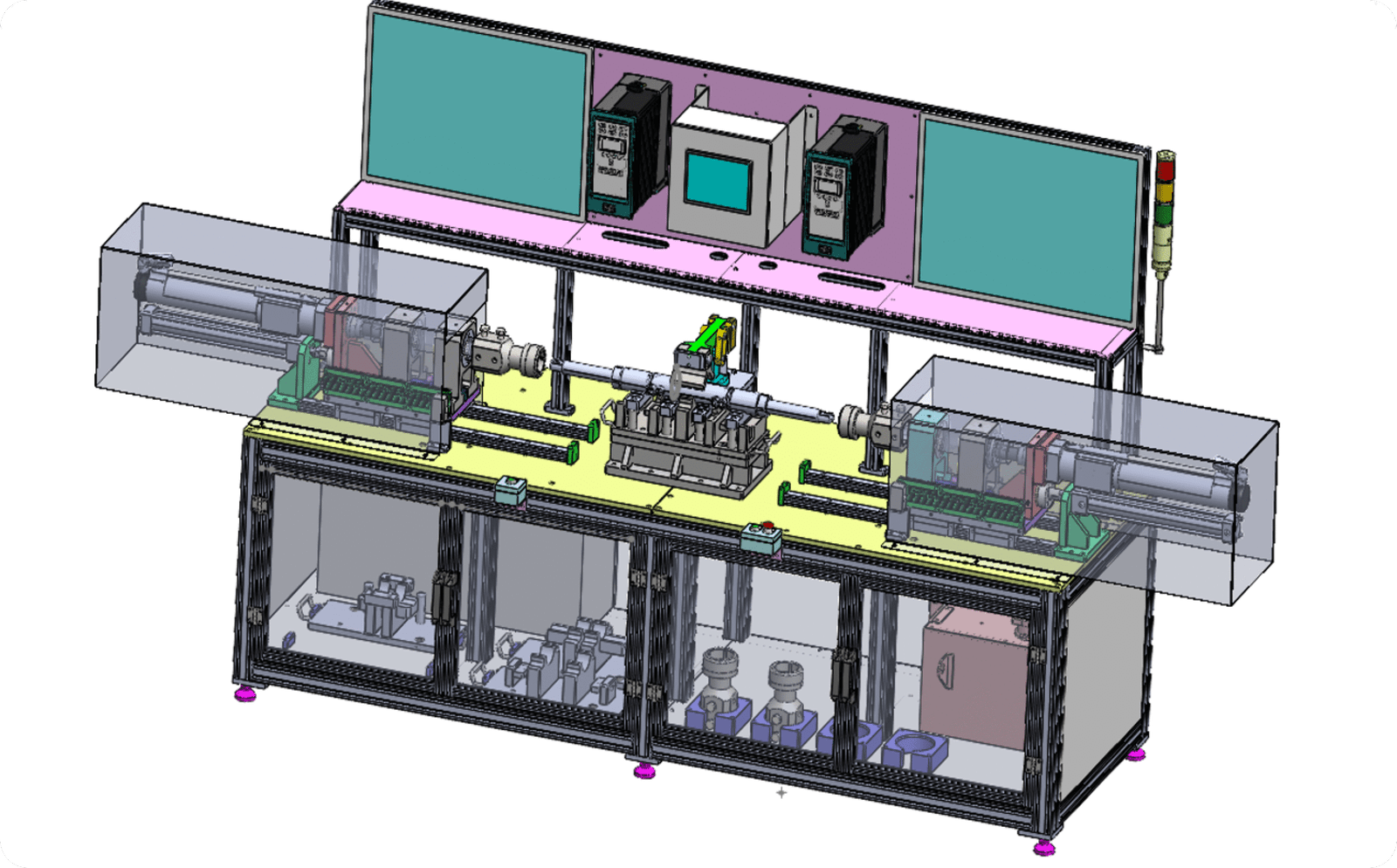

Ontario Dynamics specializes in automation design, special-purpose machines, and mechanical product development. From design-only support to complete turnkey design, we tailor every project to your needs. Our experience ensures production-ready, maintainable, and cost-effective systems.

Learn more about services →Our story and expertise

Ontario Dynamics was founded on a decade and a half of engineering experience in industrial automation, special-purpose machinery, and product development. Our expertise blends mechanical design, hydraulics, pneumatics, motion systems, and controls to create machines that are efficient, maintainable, and production-ready.

We have engineered and delivered press-line destacker feeders, ASRS systems for engine storage, EV motor pick-and-place machines, and automated inspection systems using vision and AI technologies. Our portfolio also includes test rigs and data-acquisition systems for endurance, fatigue, and vibration testing — built to validate designs before mass production.

Driven by the belief that “simple is sustainable,” we focus on reducing component count, optimizing manufacturability, and improving serviceability from the very first design iteration. Whether developing a complete automation line or supporting integrators with outsourced mechanical design, we turn engineering challenges into practical, high-performance systems.

What's Makes Us Special

Our comprehensive expertise spans across multiple engineering

domains, delivering integrated

solutions that drive industrial

innovation.

Material Handling & Motion Control

Expertise in conveyors, ASRS, gantries, and automated transfer lines.

- ✓ Automated Storage & Retrieval System

- ✓ Conveyor Belt Systems

- ✓ Gantry & Transfer Lines

Vision Inspection & Traceability

Integration of industrial camera, AI vision, and sensor-based quality detection system.

- ✓ Industrial Camera System

- ✓ AI- Powered Vision Analysis

- ✓ Quality Detection Sensors

Retro & Optimization

Upgrading legacy machines for higher throughput, accuracy, and reliability.

- ✓ Legacy System Upgrades

- ✓ Performance Optimization

- ✓ Reliability Enhancement

Design for Manufacturability

Engineering simple, robust, and production-ready system using standardized components.

- ✓ Cost - Efficient Design

- ✓ Standardized Components

- ✓ Production-Ready System

Test Rig & Data Acquisition

Design of endurance, fatigue and vibration test system with full DAQ integration.

- ✓ Endurance Test System

- ✓ Vibration Analysis

- ✓ DAQ Integration

Technologies We Work With.

Cutting-edge tools and technologies that power our innovative solutions

-

Mechanical Design & Simulation

- ✓ SolidWorks

- ✓ Solid EDGE

- ✓ Auto CAD

- ✓ FEA Analysis

- ✓ Motion Analysis

-

Automation & Control

- ✓ PLC System

- ✓ HMI INTERFACE

- ✓ Industrial Sensors

- ✓ Servo Drives

- ✓ CNC Systems

-

Prime Movers

- ✓ Pneumatic System

- ✓ Hydraulic System

- ✓ Electrical Actuation

- ✓ Motion Controls

- ✓ Drive Systems

-

Vision & AI

- ✓ Machine Vision

- ✓ 2D/3D Cameras

- ✓ Defect Detection

- ✓ Part Identification

- ✓ Vision AI Integration

-

Testing & Validation

- ✓ Strain Gauging

- ✓ Temperature Sensors

- ✓ Fatigue Testing

- ✓ NVH Analysis

- ✓ Shaker Tables

-

Manufacturing & Prototyping

- ✓ 3D Printing

- ✓ CNC Machining

- ✓ Sheet Metal

- ✓ Fabrication

- ✓ Assembly

-

Data & Connectivity

- ✓ LabView

- ✓ CAN Protocol

- ✓ Modbus

- ✓ Industrial Ethernet

- ✓ LOT Gateways

-

Design Standards

- ✓ ASME Y14.5

- ✓ ISO-GD&T

- ✓ DIN

- ✓ FMEA

- ✓ DFMDFMA Compliance

The Team

Our Office

801 York Mills Rd, Unit 200

Toronto, ON

Canada

M3B 1X7

Contact Number: +1 647-815-6097